Portfolio Deep Dive

High-precision, innovative laser measurement technology from nokra - 3 questions for Günter Lauven

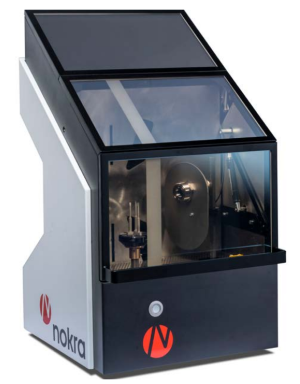

In 2019, nokra Optische Prüftechnik und Automation GmbH received the innovation award for a hot measuring cell that was implemented for the first time. Now the company is launching a new measuring device that is revolutionizing series production in forging technology and hot forming. The special feature: the 3D laser measuring system is the first of its kind to measure the complete contour of forged test pieces heated up to 1,200 °C and calculates the dimensions of the parts when they have cooled down. We spoke to nokra’s Managing Director Günter Lauven about it.

Mr. Lauven, what is innovative about the new laser measuring system from nokra?

Quite simply: up to now there has been no way of comprehensively evaluating the dimensions of formed parts that are still warm in the industrial series production process, for example in the automotive supply industry. Our measuring system predicts the subsequent cold dimensions with a very high level of accuracy and within a few seconds after forging. This makes it possible to check the forming process and the tools used after the first parts and to optimize them immediately.

That sounds like a lot of advantages for your customers ...

Absolutely. Until now, you had to wait up to two hours for the components to cool down sufficiently for a measurement. By then, a forging press may have produced many thousands of pieces. Then, of course, it's particularly annoying when the parts don't meet the geometric specifications and the entire production ends up being scrap. In the end, this not only harms the company, but also the environment and resources. Our measuring system thus saves our customers energy, CO2 emissions, material and working time.

What potential do you see for the future?

The potential customers who have been addressed so far are enthusiastic. But we are only at the beginning of the development. I consider the use of our device in connection with artificial intelligence (AI) to be particularly promising. The system can digitize and evaluate production results very efficiently. This means that the measuring cell can be used in AI developments in forming technology or other production processes by making a learning process possible on the basis of various input variables. There consists enormous potential for nokra’s future.

The innovative hot measuring cell from nokra measures components at up to 1,200° Celsius.